WAWF and IUID label printing go hand in hand. Submitting large numbers of IUID items to Wide Area Workflow (WAWF) can be the most significant challenge in UID compliance. There are many IUID touch points for defense contractors throughout the UID Life Cycle. For some contractor a single UII may come into play numerous times:

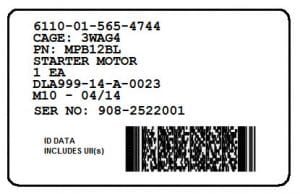

IUID Label for Mil-Std-129R Unit Container

- IUID item marking (Mil-Std-130)

- IUID container labeling (Mil-Std-129)

- Unit container label

- Intermediate container label

- Exterior container label

- Bar coded serial number lists

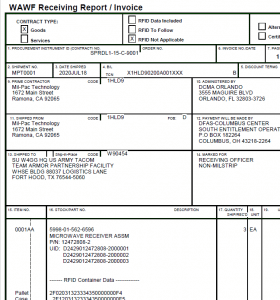

- Submission of UID data to WAWF

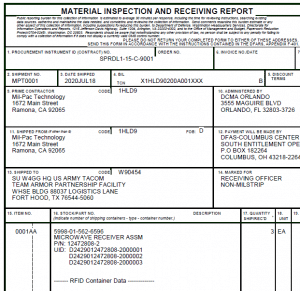

- Receiving Report (DD250)

- RFID Pack Data (with DD250 or separate Pack Update)

- Embedded UID items

- Maintenance, Overhaul, Repair of Government-Furnished Property (GFP)

- Custody transactions with IUID Registry

- IUID container labeling (Mil-Std-129)

- Submission of serviced UID data to WAWF

- Reparable Receiving Report (RRR)

- RFID Pack Data (with RRR or Pack Update)

A good software solution must be robust enough to handle all of these aspects with ease, but at the same time flexible and modular enough to be applied only where needed. MIL-Comply is designed to operate as a point solution for specific IUID challenges or handle all aspects of the entire UID life cycle. It scales from small shops to major defense enterprises.

MIL-Comply Labeling includes various IUID container label formats, like the one pictured above. But it also collects that UID data for inclusion on a WAWF DD250 Receiving Report.m This makes shipping significant numbers of UID items a lot easier. Manually entering IUID and RFID data into the WAWF web site is eliminated by the Mil-Pac WAWF Automation solution.

MIL-Comply is a robust DOD RFID solution that automatically gather UID and RFID data while it prints RFID container labels. The aggregated data is all ready to send to WAWF in a Receiving Report or RFID Pack Update. Just print and submit, even if the shipment includes RFID-tagged pallets. Of course, you might want to print all of that data out for quality assurance review, but, that is part of the solution as well.

The MIL-Comply WAWF solution integrates IUID processing into all aspects of its shipping workflow, providing a simple and seamless solution over the entire IUID Life Cycle. With MIL-Comply you may:

- Easily add IUIDs to shipments for

- Printing IUID container labels (Mil-Std-129R)

- Association with RFID labels to automate WAWF submission

- Submission to WAWF in DD250 Receiving Reports

- Easily embedded UID children for WAWF Receiving Reports

- Print Mil-Std-130 IUID part mark labels using laser and thermal transfer printers.

The goal of any DOD shipping compliance solution, beyond complying with the multiple standards, should be to avoid entering data more than once. Ideally you should be able to print DOD IUID labels and submit to WAWF without any additional data entry.

[Note that WAWF allows only first-level embedded items in Receiving Reports. Use Comply/RFID Expeditor to send more deeply embedded items, or as an alternative method.]

MIL-Comply submits IUID data to WAWF and the IUID Registry so you do not have to log into either system. IUIDs entered for container labeling are automatically available for electronic submission as a WAWF DD250 Receiving Report.

- Simple methods for entering/importing IUID data for WAWF Receiving Reports submitted electronically

- Register IUIDs by including them in electronic WAWF Receiving Reports

- Register embedded IUIDs by submitting on WAWF Receiving Report or directly to the DOD IUID Registry

There are four easy ways to add UID data to MIL-Comply

- Paste IUIDs, including embedded IUIDs, when printing labels or preparing WAWF Receving Report

- Import UID data from other systems

- Generate UID data while creating WAWF Receiving Reports or Mil-Std-129/130 labels

- Scan IUID barcode on the parts

- CSV import IUIDs or complete WAWF-ready shipments

Comply/Labeling IUID/UID label capabilities include both as Mil-Std-129 container labels and basic Mil-Std-130 part mark labels to thermal-transfer printers.

- Print Mil-Std-130 DOD IUID Permanent Part Labels

- Print Mil-Std-129 Container Labels (including 2D UID barcode per Revision R)

- Print RFID Container Labels with 2D UID Barcode for compliance with DOD IUID and RFID Mandates

- Print IUID/Serial Number lists (for containers with more than five items).

IUID shipments that require RFID create a challenge without a robust solution for creating Mil-Std-129R labeling with IUID and RFID. Keeping track of which UID went into what RF-tagged box can be a nightmare. The data can be long and detailed, and entering into the WAWF web site time consuming and a source of errors. Comply/Labeling collects and organizes that data as labels are printed and submits it as a WAWF DD250 Receiving Report or as a separate RFID Pack Update. This is all part of the MIL-Comply’s WAWF Automation solution.

Government-Furnished Property (GFP) service contracts present a new set of challenges to contractors, even those already used to dealing with Wide-Area Workflow (WAWF).

The first challenge is to ensure that items are shipped on a Reparable Receiving Report (RRR) rather than the standard Receiving Report (RR/DD250) used for new acquisition. Besides being a violation of DFARS, WAWF will reject RRs for items in the UID/IUID Registry. Shipping an unregistered GFP item on a standard RR creates a big problem because the item is registered as newly acquired at the cost of repair, entering service on the ship date.

Shipping GFP items on a Reparable Receiving Report (RRR) requires that the contractor have previously taken custody of them in the IUID Registry. This is because what distinguishes the RRR from a standard WAWF Receiving Report (RR) is the idea that the shipment is returning the item to Government custody. Of course, you cannot transfer what you do not possess. WAWF will also reject efforts to ship GFP items on a standard RR after discovering that they are already in the Registry.

MIL-Comply seamlessly integrates GFP processing for WAWF and the IUID Registry into the same processes used for shipping new items to the DOD.

The concept of Unique Identification (UID) has been around for quite some time, adopted decades ago by the aerospace and automotive industries to allow for interchange of parts between manufacturers and countries. Forms of UID exist in normal life, from the VIN on your car to the UPC on a can of soup. The UPC is simple in concept. Take an item number assigned by a manufacturer, add a manufacturer ID in front of it and one has a unique identifier that allows item number “00001” to at the same time represent a can of soup, a pack of gum and a box of pencils, depending on the manufacturers ID.

To make UIDs useful, a machine-readable interface, such as a bar code, is specified based on the amount of data in the UID and the environment it is to be read in. UPCs use a compressed linear barcode so they can fit on small packages and be read quickly and reliably in the retail environment. UIDs are much longer than UPCs, so the two-dimensional Data Matrix symbol is used instead.

The US Department of Defense (DOD) began to mandate the use of UIDs around 2004. As the initiative evolved the term Item Unique Identification (IUID) term replaced UID as a more precise way to refer to the DoD’s initiative and to differentiate it from other forms of unique identification. The UID acronym is still in wide use in reference to the DoD requirement, the Registry in which this data is stored and the identifier itself, which is more precisely called a Unique Identifier (UII) and/or Item Unique Identifier (IUID). Use of the more generic term UID remains popular, even if not entirely precise.

Revision P (Notice 4) of Mil-Std-129 introduced IUID (UID) label data onto container labels in the form of a two-dimensional PDF417 symbol. At fifty characters, Unique Identifiers (UII) are too long to fit on a standard four-inch wide label. Thankfully, the Standard requires only the serial number portion to be printed in the clear, while the UII is encoded into the data symbol. This allows the container’s UIIs (up to five) to be read by automated information technology.