DOD RFID labels require mastery of several disciplines in order to create compliant shipments in an efficient manner. Knowledge of RFID basics is essential to avoiding technological issues. But, getting tags on boxes is just the beginning, because there is the matter of submitting RFID data to WAWF. Companies with large shipments or high shipping frequency should consider a WAWF Automation solution. Shipping UID items really complicates data management issues, creating the need for an RFID-IUID label solution that creates compliant labels while collecting this even more complicated data for WAWF submission.

DOD RFID Label Technology

Radio Frequency Identification (RFID) is a technology that allows for the reading of container identifiers via radio waves. It offers specific advantages over linear and two-dimensional bar codes to the supply-chain.

The RFID technology used in defense contract shipments is EPC Gen 2, a passive tag operating in the 860-960 MHz band. Passive means that the tag does not actively broadcast anything, it only responds when interrogated by a compatible RFID reader. For complete specifications on tags and data formats, refer to the DoD Suppliers Passive RFID Guide. Defense contractors may, in rare circumstances, be asked to use active RFID tags, an entirely different technology and process than that specified under Mil-Std-129R.

The RFID tag is sometimes called an RFID chip or antenna. Actually, it is a combination of the two that is embedded in special label stock. Typically, they are assigned an ID during printing by an RFID-enabled thermal-transfer printer. They can also be used in their bare form, known as an inlay. RF-tags respond with their assigned ID when RFID readers bounce radio waves off of them, in what is referred to as passive RFID tag interrogation.

RFID Label Formats

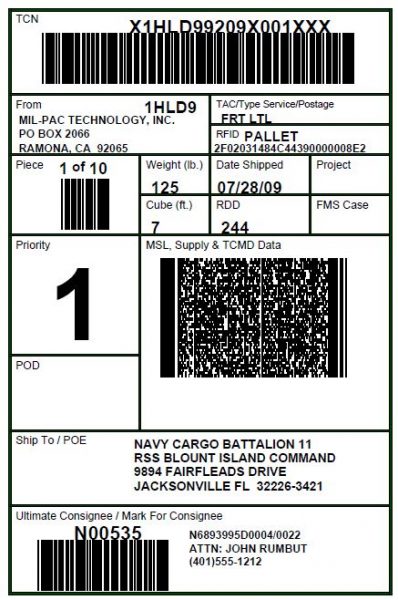

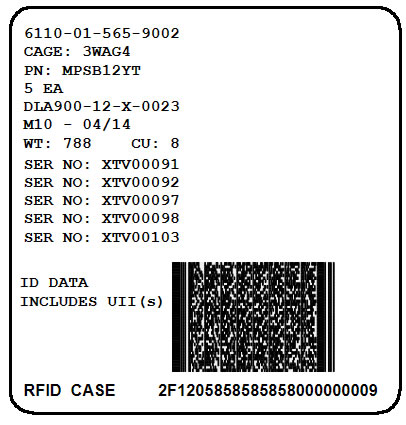

Mil-Std-129 does not prescribe a specific format for RFID labels. RF tags may be integrated into a standard Military Shipment Label(MSL) or exterior container label [¶5.9.2.1]. Generic RFID labels or unprinted inlays may be used. The standard stresses the importance of ensuring that each “RFID tag be affixed at a suitable location where there is a minimum risk of damage… and the highest potential for successful passive RFID tag interrogation [Mil-Std-129R ¶5.9.2.1].

RFID Label Format Selection

There are several factors to consider when deciding which RFID-enabled label format to use. Tag placement, data collection methodology and cost all come into play. Tag placement for palletized unit loads may also impact choice of format, and is discussed below.

The standard suggests use of the address label (MSL) for loose containers, but also recognizes that the palletized containers will usually (not) be marked with an address label, and therefore require only that the passive RFID be affixed at a suitable location [¶5.9.2.2]. The exterior container label might make a better choice as an RF tag, since it can be used for both the pallet and the individual cases. And as discussed below under Data Collection, use of the exterior container label simplifies preparation of RFID data for submission to WAWF.

Using the RF-tag exterior container labels for both the container and the pallet makes it easy to collect the IDs of the cases so that they may be reported in association with the pallet ID. Of course, given the cost of RFID-capable printers, the use of pre-printed generic formats may be the answer.

RFID Tag Placement

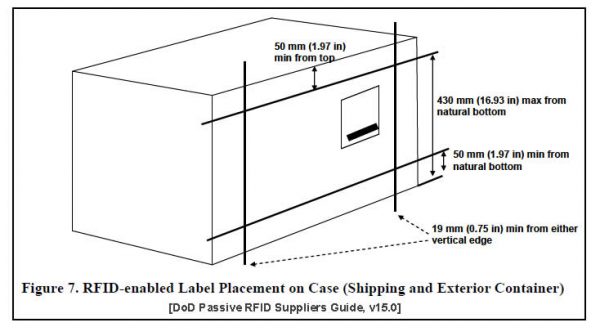

Damage to tags is avoided by taking care not to place tags where physical contact is likely during handling. Tags should not be placed over box seams where they could be destroyed by the container being opened. Placement of tags for successful interrogation comes with experience and testing. Understanding the physics of radio waves helps, but trial and error works too.

When choosing to use RFID-enabled MSL or exterior container labels, the placement of these labels must be consistent with ¶5.3.2. However, this might result in unreadable tags due to the nature of the container contents. Should this problem occur, use of a generic RFID label may be called for, since the rules for its placement, as defined by the DoD Passive RFID Suppliers Guide, are more relaxed.

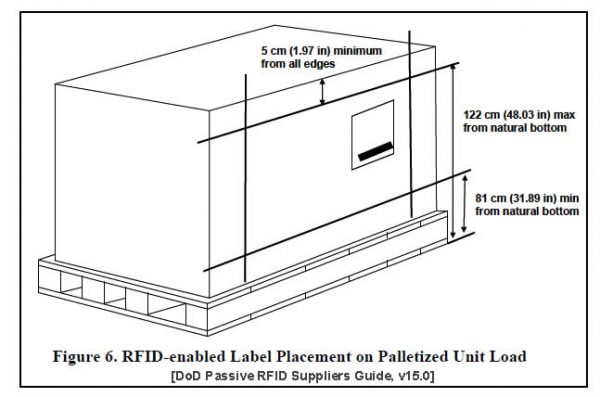

The placement of RFID tags on palletized unit loads must meet the same criteria for readability and survivability. Additional care must be taken to ensure that the pallet tag does not interfere with any container tag. A four-inch separation is recommended. The pallet tag should not be attached to any of the containers, as may cause confusion after the pallet is broken apart (singulated). [¶5.9.2.1b]

A common question regards the possible need for a pallet tag on containers large enough to require a pallet for handling. Because this is a single container, it is referred to as a skidded load, requiring only a container (Case) tag. Palletized loads are created two or more exterior containers are placed on a pallet with the intention of be treated as a single entity. In such situations, each exterior container(Case) is tagged. The pallet receives its own (Pallet) tag, and the data associated with it summarizes the contents of the pallet, so that the Case tags do not have to be read. In some densely packed pallets, not all of Case tags may read successfully.

Submitting RFID Data to WAWF

An RFID Tag is mostly just a sequential number assigned by shippers. It is sometimes referred to as a license plate because it bears no information about the contents of the container to which it is attached. RFID tags are useless to the DOD without additional data that associates RF tag IDs to contract items.

Defense contract shippers must report the contents of each container that is RFID-tagged in terms of the contract line item (CLIN) and quantity, and UIIs if the items have UID markings. For palletized unit loads, the RF-tag ID of each container must be associated with a RF-tag for the pallet itself. This data is either manually entered into Wide-Area Workflow(WAWF), or transmitted to WAWF as part of an EDI-856 Receiving Report or Pack Update. In some cases, RFID data is provided to DoD via an EDI-856 Advance Shipment Notice, similar to that sent to WAWF.

By the time shipments arrive at their first destination, often a DLA depot, the RFID data collected by the shipper is waiting in the depot’s receiving system. As RF tags are read they are compared to those expected by the depot, and just like magic, the depot knows what it has received.

Collecting RFID Data

There are a number of different ways to collect RFID data to be sent to WAWF. You could apply RFID inlays to each container and then read the tags with a handheld scanner, or as they pass through a reader portal. If palletizing, you could place the tagged containers on a pallet wrapper and read the RFIDs as the pallet spins around.

The easiest way to collect RFID data is to record the contents of each container as its RFID-enabled container label is being printed. As the CLIN, quantity and UII data being printed on the label, they can easily be associated with the label’s RFID. This information can then be entered into WAWF manually, or submitted to WAWF as an EDI-856 transaction through an automated electronic process.

The use of a container label for RFID purposes departs from Mil-Std-129R’s recommendation to use the address label as the RF-tag carrier. However, this is merely a recommendation, and contractors are free to use “a separate location on the shipment” [¶5.9.2].

It may be necessary to affix the tag outside of the acceptable address/identification area [¶5.3.2] due to the contents of the container, which can interfere with the radio waves interrogating the RFID antenna. See Tag Placement, above.

Components of a Radio Frequency Identifier

Most labeling software will build unique, compliant RF-tag IDs automatically. However, it is good to know a little about how IDs are constructed, especially the critical container level indicator, explained below.

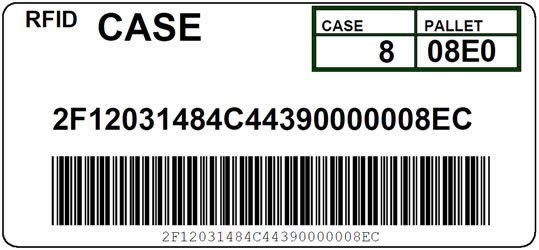

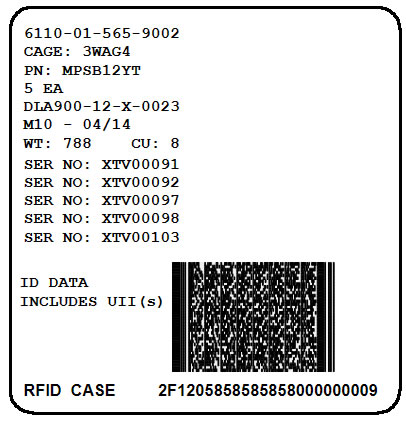

DOD 96-bit Case Tag ID: 2F12031484C443900000004E

There are four components of an EPC 96-bit RF Tag ID, which are always twenty-four(24) hexadecimal digits (0-9, A-F):

- The first two characters (2F) indicate that the tag is a DoD-96 construct.

- The third character (1) is the container level filter, described below.

- The next twelve characters (2031484C4439) are the hexadecimal representation of the shipper’s CAGE Code, and a leading space (20). In this example, 2031484C4439, is hex for “1HLD9”.

- Finally, the last nine characters are the serial number of the tag, as assigned by shipper. In this case, 00000004E is hexadecimal for 78. RF-tag serial numbers can go up to 68,719,476,735, so there is little worry about running out.

RFID Tag Container Levels

There are three container levels defined by the DOD RFID Initiative: Pallet, Case and Unit, as identified by RF-tag IDs starting with 2F0, 2F1, and 2F2, respectively. It is critically important that the tag types are used correctly for each container level. Using the wrong container-level tag may cause a shipment to be sidelined for exception processing, delaying its receipt.

The Unit tag is currently required for only a very small number of defense contracts. Unless your contract explicitly states a unit-level requirement, do not tag below the case level.