Basic Mil-Std-129R labeling is straightforward enough, but RFID and IUID requirements make it much more challenging. The two-dimensional (2D) PDF417 symbol must include the serial number or IUIDs of items in the container. One challenge is collecting and organizing IUID and RFID data for submission to WAWF, when applicable. A robust DOD shipment labeling solution which includes WAWF automation saves time and eliminates costly errors by using labeling data for go generate WAWF DD250 Receiving Reports for Wide Area Workflow.

Mil-Std-129R compliance covers a wide range of labeling situations, including the need to support RFID and the inclusion of IUID data in the label’s two-dimensional (2D) PDF417 symbol. Besides including RFID and IUID data on labels, this data must be collected and organized for submission to WAWF. This makes a robust and highly integrated WAWF automation solution very important.

MIL-Comply/Labeling supports:

- Unit and Intermediate Containers

- Exterior Containers

- Military Shipment Labels (MSL)

- UID Container labels with 2D PDF417 symbols

- Barcoded Serial Number Lists for more than five SNs or IUIDs

- RFID-enabled labels

See more examples of Mil-Std-129R labels.

Need to know more about labeling? See the Mil-Std-129 Compliance Guide.

Robust Mil-Std-129R Labeling with RFID and IUID Integration

MIL-Comply Labeling is a robust standalone solution for Mil-Std-129R labeling. However, its capabilities are integrated throughout the MIL-Comply product footprint making it a powerful solution for both single users and enterprise-sized teams that need to do:

- WAWF Receiving Report (DD250) / Combo transactions

- VSM Automation (for DLA Vendor Shipment Module)

- IUID labels for Government-Furnish Property (GFP shipping containers)

- GSA Order Labeling for shipping to

- End Users (Fed-Std-123H)

- DLA Depots (Mil-Std-129R)

- Generate IUID labels throughout

- Automate RFID Labeling (from import data files)

- Automate Container Labeling from scanned IUID Items

- Import IUID items from CSV for WAWF-ready shipments

Linear Barcodes vs 2D Symbols for Mil-Std-129 Labels

The use of linear bar codes on defense shipment containers goes back to the LOGMARS

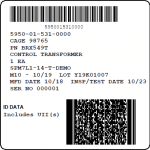

Unit Container with Linear and 2D Bar Codes

standard, which was leading edge in the 1980s. Linear bar codes have, and continue to, serve an important purpose. And just like the linear UPC labels found on everything we buy in the private sector, they may continue to serve a purpose.

The downside of linear barcodes, at least with their traditional Mil-Std-129 use is that they require context in order to be useful to automated systems. At one point, MS-129 Revision P required up to nine linear barcodes on a package (that contained five serialized items). Designing automated systems to process such a label depends on reading them in the right order or recognizing the characteristics of the data (number of digits in an NSN versus a contract number).

The advantage of the PDF417 symbol is that encoded data is laid out in a standardized data structure, each data item prefixed by a Data Identifier specified by Mil-Std-129R. The downside of PDF417 is that requires more complex, sensitive and expensive scanners than linear barcodes, along with software that can extract the desired data from the PDF417 data structure defined by Mil-Std-129R.

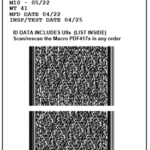

Macro PDF417s for Excessive UID Quantities

Containers with more than five UID items are often handled by the listing the UIDs on barcoded serial number lists. These include multiple standalone PDF417 symbols capable of being read by standard scanners and software. Adoption of the Macro PDF417 barcode symbol allows the UID Container data to be extended over as many 2D symbols as needed to include all of the UIIs in a container. The use of barcoded serial number lists is still relevant as they allow for processing the UID data separately from the container, including after the container has been removed. [This feature requires Release 1.6.0248, or later.]

Comply/Labeling offers formats with linear barcodes and/or 2D symbols to meet your customer’s requirements.

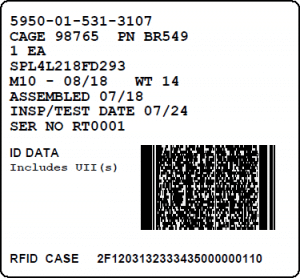

Mil-Std-129R RFID Exterior Container Label

RFID Container Labels

Printing RFID labels is pretty easy. The challenge is collecting and organizing the data describing the contents, starting with the CLIN and quantity. And if there are IUIDs in the box, all of those must be associated with the RF Tag, along with the pallet each container is placed on. All of this data must be submitted to Wide Area Workflow (WAWF). MIL-Comply does all of that automatically, and can submit in an EDI Receiving Report (DD250) or Pack Update.

Mil-Std-129R defines the technical requirements for compliance with the DoD RFID Mandate. It also talks to how RF Tags should be deployed on containers. However, it falls short of defining what an RFID label should look like, primarily because there is no requirement for any visible indication that containers are RFID tagged. Tags may be integrated into the Military Shipment Label, Exterior Container Label or a Generic RFID label, or simply stuck on the box (usually under a label for protection).

More information is available:

Submitting RFID Data to WAWF

There are three ways to submit RFID data to Wide Area Workflow:

- Enter it into the WAWF web site (which is loads of fun)

- Include it in the WAWF Receiving Report submitted as an EDI transaction

- Submit a separate RFID Pack Update submitted as an EDI transaction

The latter two options are two ways to achieve automated RFID compliance for DOD shipping. You can choose to send RFID Pack Updates whether you submit Receiving Reports electronically or enter them into the WAWF website. They are very useful if your shipments have lots of RFID containers or IUID items. Also very useful for third-party logistics service providers, allowing them to submit RFID data on behalf of a prime contractor while the prime maintains control over their Receiving Report and invoice.

IUID Data Integration

UID compliance starts with marking items as specified by Mil-Std-130. But that is just the start, with container labeling, RFID and WAWF creating a definite need for integrating UID data management across those processes.

Unique Item Identifiers (UII) need to go onto IUID container labels that are printed in compliance with Mil-Std-129R. That can involve Unit, Intermediate and Exterior Container Labels. If more than five UID items are in a container, the UIIs must appear on a Barcoded Serial Number List. RFID container data for UIDs must be collected and combined with a list of UIIs for submission to Wide Area Workflow (WAWF).

All of this makes a case for a company’s Mil-Std-129 labeling system to either drive IUID part marking, or have efficient methods of inputting or collecting them. Importing IUIDs with a CSV file should be considered for shipments with lots of UID items. It will save a lot of time and errors both for labeling and WAWF submission.

Other Automation Opportunities

Other opportunities to save time and effort include:

- VSM Automation which eliminates the need to use DLA’s Vendor Shipment Module website

- Receiving DIBBS purchase orders from DLA via EDI, which eliminates entering label data and can be combined with WAWF Invoicing automation.