Proper use of the Military Shipment Label (MSL) will help ensure that shipments are properly processed at Defense Depots, which is essential to timely payment. The purpose of the MSL, as defined by Mil-Std-129R is to identify shipments to the DOD in a unique and immediately recognizable way.

The MSL is designed to work in conjunction with Mil-Std-129R-compliant container labels, such as the exterior container format. The two labels are used together, but each has its own specific purpose. MSLs never appear with the unit and intermediate container labels. This is true even when the exterior container serves as the unit container as well. In such cases, exterior format rules apply.

The Military Shipment Label (MSL) is placed on:

- Each loose (non-palletized) case or shipping container (crate)

- Each palletized unit load (but not on each case on the pallet)

- Each full rail car or full truckload

Cases that are palletized simply for the convenience of handling and shipping are not considered to be a palletized unit load. Each such container should be marked with an MSL.

Mil-Std-129R defines two versions of the MSL, which differ in the data required and how it is encoded in the PDF417 symbol:

- Generic Cargo – used for Defense contract shipments

- Unit Move – used by military units when moving their equipment.

Components of the Military Shipment Label (MSL)

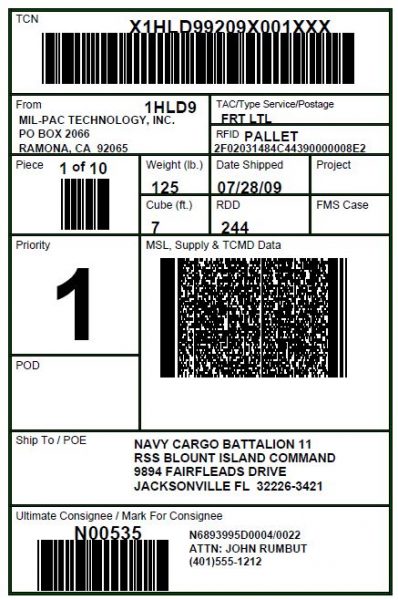

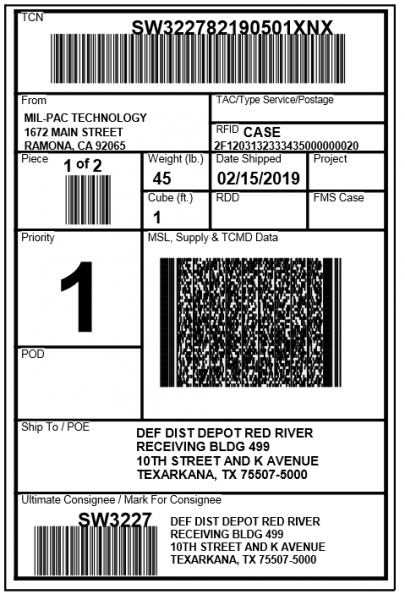

In practice, these Mil-Std-129R labels identify the supplier, the final destination of the shipping container and other necessary information pertaining to the shipment. There are three primary components to these labels – human readable information, linear bar codes, and a two-dimensional PDF417 bar code symbol. Some components contain multiple pieces of data.

Required MSL Markings

MSL markings consist of both human readable and bar coded information on a recommended 4×6 inch label. The exact format of the MSL is not mandated by the standard, as long as the required data is included along with compliant linear and 2D bar codes. Mil-Std-129R includes “figures 2A and 2B (as) examples of acceptable MSL formats that may be used as guidelines in producing a label.” [¶5.2.2.3]

Required human readable information (contractor shipments) [¶5.2.2.5]:

- Transportation Control Number (TCN)

- Transportation Account Code (TAC)/Postage (rarely applies to contractor shipments).

- From – CAGE and address of the shipping activity

- Type Service – The type of transportation service to the “ship to” address (such as Frt LTL, Air Expss, Expss Mail, etc.)

- Ship To Address and DODAAC

- POE – the three-digit air/water Point of Embarkation code (rarely applicable)

- Transportation Priority (1, 2, 3, or 4)

- POD – air/water Point of Debarkation three-digit code (rarely applicable)

- Project code, when applicable

- Ultimate Consignee DODAAC (barcoded)

- Mark-For Consignee address or instructions

- Weight – Gross weight (pounds), rounded to the next whole digit

- RDD – Required delivery date code, day of year (Julian date), if specified by the requisitioner

- Cube – Container volume (cubic feet), rounded to the next whole digit

- Date shipped (in the clear, e.g. DD-MMM-YYYY or MM/DD/YYYY)

- FMS (foreign military sales) Case Number, as appropriate

- Piece Number – the piece number of the cargo within the TCN for this shipment unit

- Total Pieces – Total number of pieces within the TCN for this shipment unit

Required Bar Coded Information:

- Code 39 linear barcodes:

- Transportation Control Number (TCN),

- Piece number

- Ultimate Consignee/Mark-For DODAAC. When the Mark-For is other than an address (with DODAAC) the Ship-To DODAAC should appear in text and bar code.

- A single two-dimensional (2D) bar code in a PDF417 symbol is required. Much of the data that appears on the MSL is encoded in the PDF417. The data structure of the symbol is defined by Mil-Std-129R Table A-I and A-II.

- TCMD (Transportation Control and Movement Document) is rarely required for contractor/vendor shipments. “For contractor or vendor shipments, the TCMD information in the 2D (PDF417) bar code, when required, shall be coordinated between the contractor or vendor and the contracting office or administrative contracting office, per the FAR 47.305-10 and the DFARS 247.305-10 and 247.371.” [¶5.2.2a]

Usage and Placement of MSL

The proper Military labels are required for all shipment units* to the DoD. In most cases, a single MSL is placed on each loose shipping case or shipping container (crate), on each palletized unit load* (one per pallet only), or on each full rail car or full truckload. The MSL must be applied on the upper left side of the shipping container. The label may not interfere with other required markings, cleats, strapping or closure tape on the container. Additionally, the MSL may not be placed on the top or bottom of the container unless otherwise specified in your contract.

*A Shipment Unit is commonly understood to be the outermost, non-palletized container by which the shipment will be handled.

RFID Military Shipment Label

There are advantages to using the exterior container label for RFID tagging over the MSL. Read more about RFID data collection to learn more about use of RFID-enabled exterior container and use of generic RFID labels.

A passive RFID tag may be integrated with the military or commercial shipping label (RFID-enabled address label) or it may be placed in a separate location on the shipment. (The) standard identifies recommended locations for the RFID-enabled address label and passive RFID tag placement.

[Mil-Std-129R ¶5.9.2]

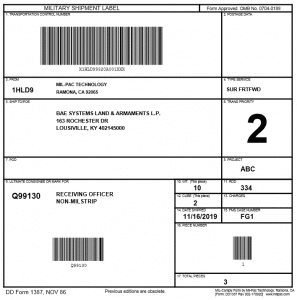

Use of DD1387 Form

DD1387 – Original Military Shipment Label

The use of DD Form 1387, superseded by the MSL, is used under these circumstances: “Attach a DD Form 1387 (Military Shipment Label) in lieu of a bar coded MSL for DoD contingency operations where manual entry is the only means available to document DTS shipments.” [Mil-Std-129R §5.2.1]

Learn more about:

- DOD RFID Compliance

- The Mil-Comply Mil-Std-129R Labeling Solution

- Free Military Shipment Label Software